- High School

- You don't have any recent items yet.

- You don't have any courses yet.

- You don't have any books yet.

- You don't have any Studylists yet.

- Information

EXPERIMENT 3: FRICTION LOSSES IN PIPES

Mechanical engineering (bmm), university of malaysia of pahang.

Recommended for you

Students also viewed.

- Extended Payment TERM Requests 24 Oct 2023

- Casting Manufacturing Lab Report

- Group 6 LAB 2 Impact Test

- بحث منى الاشقر نهائي - fgfg

- LAB 6 Report ( Group 4 Section 03)

- 8 Free Fall Experiment

Related documents

- Group D Safety LAB Report M01

- ME LAB Repoert (Benchwork)

- 6 (SR) Transformation of Stress Strain

- mechanical technology lab 1 dmm1911 t7gt0gygygyhyjhy8j8jguyhguyhgyjgyjuguyhgu8480gj08hjg78yh5jg87j5h78gh57hg85hg5huyhhh

- [ Labsheet 4] Fatigue TEST

- 1. [Labsheet 2] Compression Test

Preview text

In Engineering Fluids Mechanics Lab, we had to conduct our first experiment and come out with complete report. The title for the experiment is “Determination of Friction Losses in Pipes”. It is necessary to estimate the head loss that occurs due to the flow of the fluid through the pipelines. We are considering the velocity of flowing fluid, roughness and diameters of pipes that will be shown the Reynolds Numbers. So based on the Reynolds Numbers, we will calculate it to determine whether it is turbulent flow or laminar flow. In this experiment we have four different types of pipes which are straight pipe, elbow pipe, bend pipe, 45° angle pipe. With considering Darcy Weisbach friction factor, velocity of flow in pipe, diameter of pipe and length of pipe, we will obtain the result of head loss that due to the friction in those pipes.

i. To design and evaluate complete measurement technique and experiment procedure for fluid flow and determine major and minor losses in the different piping system. ii. To investigate the head loss with different velocity.

As an incompressible fluid flows through a pipe, a friction force along the pipe wall is created against the fluid. The frictional resistance generates a continuous loss of energy or total head in the fluid and hence decreases the pressure of the fluid as it moves through the pipe. There are four factors that determine friction losses in pipe which are

i. The velocity of the fluid ii. The size (inside diameter) of the pipe iii. The roughness of the inside of pipe iv. The length of the pipe

Darcy Weisbach equation is commonly used for computing the loss of head due to friction in pipes. It is given by,

2 2 Dg where , hf = loss of head due to friction L = length of pipe D = diameter of pipe V = mean velocity of flow in the pipe f = Darcy Weisbach friction factor.

In addition to energy or head loss due to friction, there are always head losses in pipes due to an enlargement or contraction of the flow section, bends, junctions, valves etc., which are commonly known as minor losses.

For calculation of minor losses, 203 mm long PVC elbow, 322 mm long 90 o bend, 247 mm long 45o bend will be used. The internal diameter of the elbow and bends is 17 mm. Thus, the minor losses may be expressed in terms of the velocity head once the loss coefficient has been determined

2 THEORETICAL BACKGROUND

i. The parallax error should be avoided while taking readings ii. When fluid is flowing, there may be a fluctuation in the manometer reading, note the mean position carefully. iii. Carefully keep some level of fluid in inlet and outlet supply tank.

4 RESULT AND DISCUSSION

Assumption :

Roughness of the PVC pipe is smooth, = 0 mmɛ Water condition at 25°C, μ =0 x 10 − 3 kg / ms

Given data :

Straight Pipe

Length of pipe, 𝐀 = 800 mm = 0

Internal diameter of PVC straight pipe = 20 mm = 0

Based on the appendix, table 1

Volume Flow Rate, m³/s

Head Loss, m

Measured Friction Coefficient

Velocity, m/s

Reynolds Number, Re

Calculated Coefficient of Friction

Calculated Head Loss, m 0 2 0 1 34050 0 0. 0 2 0 1 32414 0 0. 0 3 0 1 31344 0 0. 0 3 0 1 29563 0 0. 0 3 1 1 25145 0 0. 0 3 1 0 21869 0 0.

Sample Calculation:

Measured head loss, h = ∆ Pρg = 28000997 x 9 Pa =2 m

Flowspeed ,V = 4 π dQ 2 = 4 ( π 0(0) 2 )=1 m / s

Reynold Number , ℜ= ρvdμ =( 997 ) (1) (0) 0 × 10 − 3

Measured frictioncoefficient , f = 2 l vhdg 2 = 2 (2(0)()(0.021)(9 2 ) ) = 0.

−1 log¿ ¿ ¿ Calculated Frictioncoefficient ,f =¿ −1¿ ¿¿ ¿ ¿

Head loss,h = fl v

2 (0) (9) =0 m

Length of PVC elbow pipe = 203 mm = 0

Internal diameter of PVC elbow pipe = 17 mm = 0.

Based on the appendix, table 2

Calculated Head Loss, m 0 1 0 2 41400 0 0. 0 1 0 2 40898 0 0. 0 1 0 1 34528 0 0. 0 2 2 1 27824 0 0. 0 2 1 1 27573 0 0. 0 3 2 1 26785 0 0.

0 2 0 1 34527 0 0.

0 3 1 1 29583 0 0., 0 3 1 1 28243 0 0., 0 2 1 1 24052 0 0..

Measured head loss, h = ∆ Pρg = 17000997 x 9 Pa =1 m

Flowspeed ,V = 4 π dQ 2 = 4 ( π 0(0) 2 )=2 m / s

Reynold Number , ℜ= ρvdμ =( 997 ) (2) (0) 0 × 10 − 3 = 41818

Measured frictioncoefficient , f = 2 l vhdg 2 = 2 (1(0)()(0.0172)(9 2 ) ) = 0.

45° Bend Pipe

Length of PVC 45° pipe angle = 247 mm= 0

Internal diameter of PVC 45° pipe angle = 17 mm = 0

Based on appendix, table 4

Calculated Head Loss, m 0 2 0 2 42825 0 0. 0 1 0 2 41819 0 0. 0 2 1 1 31847 0 0. 0 2 1 1 27991 0 0. 0 3 1 1 27406 0 0. 0 2 1 1 26232 0 0.

Measured head loss, h = ∆ Pρg = 22000997 x 9 Pa =2 m

Flowspeed ,V = 4 π dQ 2 = 4 π (0(0) 2 )=2 m / s

Reynold Number , ℜ= ρvdμ =( 997 ) (2) (0) 0 × 10 − 3

Measured frictioncoefficient , f = 2 l vhdg 2 = 2 (2(0)()(0.0172)(9 2 ) ) = 0.

4.2 DISCUSSIONS

20000 22000 24000 26000 28000 30000 32000 34000 36000 0

Measured & Calculated Friction against Reynold's number

Measured Friction Coefficient Calculated Coefficient of Friction

Reynold's number, Re

Friction Coefficient, f

From the graph above, we can observe that the measured coefficient of friction and

calculated coefficient of friction decreases as the Reynolds number increases. The coefficient

of friction depends on the roughness and diameter of the pipe.

0 1 1 1 1 1 1 1 2 2 2 2.

Measured & calculated head loss against velocity

Head Loss, m Calculated Head Loss, m

Head loss,m

From the graph, we can observe that the value of measured and calculated head loss increases as the velocity of the water increases in elbow pipe. The data measured for the head loss is inaccurate and it is actually increased as the velocity of the water increases. So, the head loss is directly proportional to the velocity of water in elbow pipe.

26000 28000 30000 32000 34000 36000 38000 40000 42000 44000 0

From the graph above, we can observe that the measured coefficient of friction and calculated coefficient of friction decreases as the Reynolds number increases. The coefficient of friction depends on the roughness and diameter of the pipe

90 ° Bend pipe

0 1 1 1 1 2 2 2.

From the graph, we can observe that the value of measured and calculated head loss increases as the velocity of the water increases in bend pipe. The data measured for the head loss is inaccurate and it is actually increased as the velocity of the water increases. So, the head loss is directly proportional to the velocity of water in bend pipe.

24000 26000 28000 30000 32000 34000 36000 38000 40000 42000 4 04000

From the graph above, we can observe that the measured coefficient of friction and calculated coefficient of friction decreases as the Reynolds number increases. The coefficient of friction depends on the roughness and diameter of the pipe.

Throughout this experiment, we observed that the head loss is increased when the velocity increase and from the equation we know that the velocity is directly proportional to flow rate. There is some non-moving liquid which is near to the pipe surface and this liquid will reduce the inner diameter of the pipe and since the inner diameter reduced, the velocity of the fluid flow will increase. Therefore, the velocity of the fluid flow will increase the friction hence the head loss will be increased too.

Besides, we found that the smooth pipe has minimum friction coefficient while the friction coefficient is increased with increase of the surface roughness of the pipe. The friction factor is still not zero due to no-slip condition. When the friction coefficient is decreased, the Reynolds is increased. At very high Reynolds number, the graph showed that the factor coefficient curve is nearly horizontal hence we can conclude that friction coefficient is independent from Reynolds number. The reason is, when the Reynolds number is increased, the thickness of viscous sublayer will decrease, and therefore the thickness in the region is negligible since it is very thin where the flow is full rough turbulent flow.

4.2 QUESTIONS

a) Explain how the strain gauge senses the pressure? The main function of strain gauge in this experiment is used to measure the pressure of the water flow. Strain occurred when force is applied on any metallic wire and its length is increase or decrease. When the length of wire is decrease, its diameter will increase too hence its resistance will be decrease while when the length is decrease and its diameter will decrease. The DAQ system then converts this dimensional change in resistance into an electrical output, voltage and collected data to be further interpreted. b) Explain how you connected the measuring devices to the DAQ? In this experiment the sensor we used to determine the water flow pressure is strain gauge and we used DAQ system as the system to interpret the data from sensor. First the analog input module is connected to the NI DAQ which consist four channel ports. When everything is pre-set, we connect two wire gauges to channel 1 and 3 respectively. To collect the data from NI-DAQ software, we need to create new task at data neighborhood and choose strain as measurement then select channel 1 and 3. Lastly, we click Run then the data will appear.

c) What would happen to the head loss if; the diameter of the pipe is decrease and

the length of the pipe is decreased? To calculate the head loss, we used the formula:

Where f = Darcy Friction Factor L= length of the pipe V= mean flow velocity D= hydraulic diameter of the pipe g= gravitational acceleration

Based on the formula, head loss is directly proportional to the length of pipe while it is inversely proportional to the diameter of the pipe. Hence, when the length of the pipe decrease, the head loss will decrease too and when the diameter of the pipe

transition from laminar to turbulent flow inside the pipe. Therefore, the most significant reasons for the differences is the upstream flow fluctuation and highly disordered water flow inside the piping system. Moreover, pipe vibrations and surface roughness disturb the flow too.

5 CONCLUSION

For the conclusion, the result that obtained from both of the experiments showed that there are some different between theoretically and experimentally results. That might be caused by the lack of efficiency of sensor to detect pressure. It also may cause by the direction that we rotate using the sensor. Through the data that we received from the experiment, we found that the maximum head loss produced by 90 bend pipe°. The intermediate region downstream of any appurtenance is a mixture of friction and turbulence phenomena, and it is difficult to separate the effects of each one. Further research should be directed towards defining precise minor coefficients by taking into account all the factors involved in such head losses. Other than that, the objectives of this experiment is achieved. At the end of the experiment, we managed to determined which size of pipe and type of pipe that suitable with certain condition. We have been able to design complete measurement technique for fluid flow and determine major and minor losses in different piping system. Besides, we also being able to investigate the velocity for different diameters of pipe.

6 REFERENCES

1. Determination of flow losses in pipes, R Blauer (Colorado School of Mines), B Mitchell (Colorado School of Mines), C Kohlhaas (Colorado School of Mines), DOI: dx.doi/10.2118/4885-MS

2. "Development of radial velocity component in accelerating start-up pipe flow." European Journal of Mechanics - B/Fluids, 10.1016/j.euromechflu.2015.04. Annus, I. and Koppel, T. (2015).

3. Fluid Mechanics Fundamentals and Applications Second Edition in SI units, Yunus A. Cengel, John M. Cimbala, McGraw-Hill companies (2010)

4. Holzner, S. Use Bernoulli’s Equation to Calculate Pressure Difference between Two Points. Retrieved from dummies/how-to/content/use-bernoullis- equation-to-calculate-pressure-diff

5. Yunus A Cengel & John M (2014). Fluid Mechanics: Fundamentals and Applications (3rd edition in SI units). Singapore: McGraw-Hill Education.

6. Pipe Friction Loss. (2015, March 10). Retrieved from jfccivilengineer/pipe-friction-loss.html

29 0 1 1 0.

24 0 0 0 0., 21 0 0 0 0., 20 0 0 0 0., 17 0 0 0 0..

Volumetric flow, V (l/min)

Volumetric flow rate, V (m 3 /s)

Pressure, P1 (Bar)

Pressure, P2 (Bar)

Pressure Difference (Bar) 30 0 1 1 0. 29 0 1 0 0. 22 0 0 0 0. 20 0 0 0 0. 19 0 0 0 0. 18 0 0 0 0. Table 4

- Multiple Choice

Course : Mechanical Engineering (BMM)

University : university of malaysia of pahang.

- Discover more from: Mechanical Engineering BMM University of Malaysia of Pahang 280 Documents Go to course

- More from: Mechanical Engineering BMM University of Malaysia of Pahang 280 Documents Go to course

Want to create or adapt books like this? Learn more about how Pressbooks supports open publishing practices.

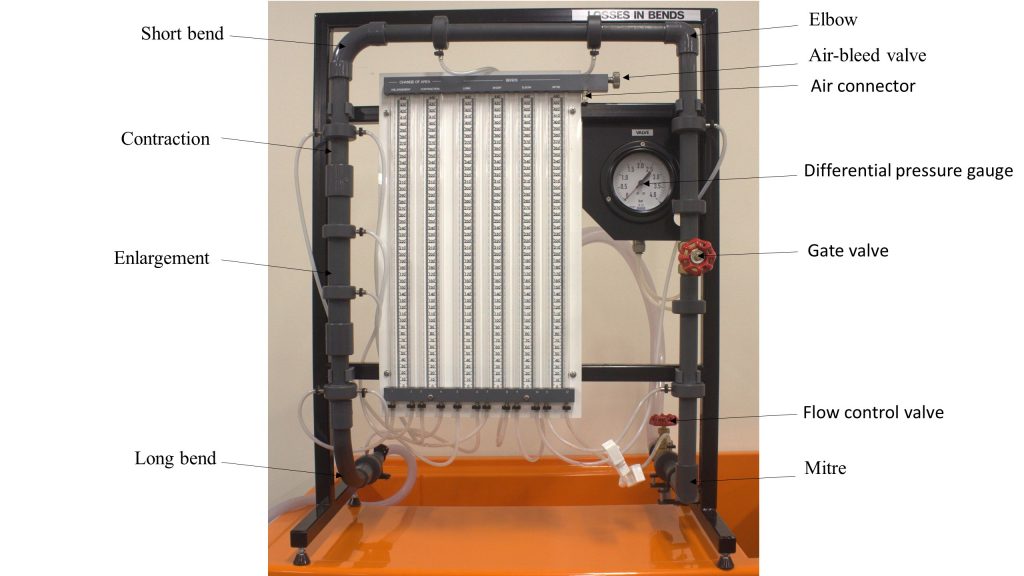

Experiment #3: Energy Loss in Pipe Fittings

1. introduction.

Two types of energy loss predominate in fluid flow through a pipe network; major losses, and minor losses. Major losses are associated with frictional energy loss that is caused by the viscous effects of the medium and roughness of the pipe wall. Minor losses, on the other hand, are due to pipe fittings, changes in the flow direction, and changes in the flow area. Due to the complexity of the piping system and the number of fittings that are used, the head loss coefficient (K) is empirically derived as a quick means of calculating the minor head losses.

2. Practical Application

The term “minor losses”, used in many textbooks for head loss across fittings, can be misleading since these losses can be a large fraction of the total loss in a pipe system. In fact, in a pipe system with many fittings and valves, the minor losses can be greater than the major (friction) losses. Thus, an accurate K value for all fittings and valves in a pipe system is necessary to predict the actual head loss across the pipe system. K values assist engineers in totaling all of the minor losses by multiplying the sum of the K values by the velocity head to quickly determine the total head loss due to all fittings. Knowing the K value for each fitting enables engineers to use the proper fitting when designing an efficient piping system that can minimize the head loss and maximize the flow rate.

3. Objective

The objective of this experiment is to determine the loss coefficient (K) for a range of pipe fittings, including several bends, a contraction, an enlargement, and a gate valve.

The head loss coefficients are determined by measuring the pressure head differences across a number of fittings that are connected in series, over a range of steady flows, and applying the energy equation between the sections before and after each fitting.

5. Equipment

The following equipment is required to perform the energy loss in pipe fittings experiment:

- F1-10 hydraulics bench,

- F1-22 Energy losses in bends apparatus,

- Stopwatch for timing the flow measurement,

- Clamps for pressure tapping connection tubes,

- Spirit level, and

- Thermometer.

6. Equipment Description

The energy loss in fittings apparatus consists of a series of fittings, a flow control valve, twelve manometers, a differential pressure gauge, and an air-bleed valve (Figure 3.1).

The fittings listed below, connected in a series configuration, will be examined for their head loss coefficient (K):

- area enlargement,

- area contraction,

- short bend,

- gate valve, and

The manometers are tapped into the pipe system (one before and one after each fitting, except for the gate valve) to measure the pressure head difference caused by each fitting. The pressure difference for the valve is directly measured by the differential pressure gauge. The air-bleed valve facilitates purging the system and adjusting the water level in the manometers to a convenient level, by allowing air to enter them. Two clamps, which close off the tappings to the mitre, are introduced while experiments are being performed on the gate valve. The flow rate is controlled by the flow control valve [3].

The internal diameter of the pipe and all fittings, except for the enlargement and contraction, is 0.0183 m. The internal diameter of the pipe at the enlargement’s outlet and the contraction’s inlet is 0.0240 m.

Bernoulli’s equation can be used to evaluate the energy loss in a pipe system:

The energy loss that occurs in a pipe fitting can also be expressed as a fraction (K ) of the velocity head through the fitting:

K: loss coefficient, and

v : mean flow velocity into the fitting.

Because of the complexity of the flow in many fittings, K is usually determined by experiment [3]. The head loss coefficient (K) is calculated as the ratio of the manometric head difference between the input and output of the fitting to the velocity head.

Due to the change in the pipe cross-sectional area in enlargement and contraction fittings, the velocity difference cannot be neglected. Thus:

Therefore, these types of fittings experience an additional change in static pressure, i.e.:

1 bar= 10.2 m water

The loss coefficient for the gate valve may then be calculated by using Equation (4).

To identify the flow regime through the fitting, the Reynolds number is calculated as:

8. Experimental Procedure

It is not possible to measure head due to all of the fittings simultaneously; therefore, it is necessary to run two separate experiments.

In this part, head losses caused by fittings, except for the gate valve, will be measured; therefore, this valve should be kept fully open throughout Part A. The following steps should be followed for this part:

- Set up the apparatus on the hydraulics bench and ensure that its base is horizontal.

- Connect the apparatus inlet to the bench flow supply, run the outlet extension tube to the volumetric tank, and secure it in place.

- Open the bench valve, the gate valve, and the flow control valve, and start the pump to fill the pipe system and manometers with water. Ensure that the air-bleed valve is closed.

- To purge air from the pipe system and manometers, connect a bore tubing from the air valve to the volumetric tank, remove the cap from the air valve, and open the air-bleed screw to allow flow through the manometers. Tighten the air-bleed screw when no air bubbles are observed in the manometers.

- Set the flow rate at approximately 17 liters/minute. This can be achieved by several trials of timed volumetric flow measurements. For flow measurement, close the ball valve, and use a stopwatch to measure the time that it takes to accumulate a known volume of fluid in the tank, which is read from the hydraulics bench sight glass. Collect water for at least one minute to minimize errors in the flow measurement.

- Open the air-bleed screw slightly to allow air to enter the top of the manometers; re-tighten the screw when the manometer levels reach a convenient height. All of the manometer levels should be on scale at the maximum flow rate. These levels can be adjusted further by using the air-bleed screw and the hand pump. The air-bleed screw controls the air flow through the air valve, so when using the hand pump, the bleed screw must be open. To retain the hand pump pressure in the system, the screw must be closed after pumping [3].

- Take height readings from all manometers after the levels are steady.

- Repeat this procedure to give a total of at least five sets of measurements over a flow range of 8 – 17 liters per minute.

- Measure the outflow water temperature at the lowest flow rate. This, together with Figure 3.2, is used to determine the Reynolds number.

In this experiment, the head loss across the gate valve will be measured by taking the following steps:

- Clamp off the connecting tubes to the mitre bend pressure tappings to prevent air being drawn into the system.

- Open the bench valve and set the flow at the maximum flow in Part A (i.e., 17 liter/min); fully open the gate valve and flow control valve.

- Adjust the gate valve until 0.3 bar of head difference is achieved.

- Determine the volumetric flow rate.

- Repeat the experiment for 0.6 and 0.9 bars of pressure difference.

9. Results and Calculations

Please visit this link for accessing excel workbook for this experiment.

9.1. Results

Record all of the manometer and pressure gauge readings, as well as the volumetric measurements, in the Raw Data Tables.

Raw Data Tables

Part a – head loss across pipe fittings, part b – head loss across gate valve, 9.2. calculations.

Calculate the values of the discharge, flow velocity, velocity head, and Reynolds number for each experiment, as well as the K values for each fitting and the gate valve. Record your calculations in the following sample Result Tables.

Result Table

Part b – head loss across pipe fittings.

Use the template provided to prepare your lab report for this experiment. Your report should include the following:

- Table(s) of raw data

- Table(s) of results

- Comment on any relationships noticed in the graphs for Parts A and B. What is the dependence of head losses across pipe fittings upon the velocity head?

- Is it justifiable to treat the loss coefficient as constant for a given fitting?

- In Part B, how does the loss coefficient for a gate valve vary with the extent of opening the valve?

- Examine the Reynolds number obtained. Are the flows laminar or turbulent?

Applied Fluid Mechanics Lab Manual Copyright © 2019 by Habib Ahmari and Shah Md Imran Kabir is licensed under a Creative Commons Attribution 4.0 International License , except where otherwise noted.

Share This Book

- Privacy Policy & Disclaimer

- Career and Professional Development

- Renewable Energy

- Hydraulic System

- Engineering Materials

Recent Updates

Major and minor losses in pipes, major head loss.

Minor Head loss

We have started something new and exciting .....

Bright Idea Space

We have started another website i.e. https://brightideaspace.com/ that basically provides the new ideas, Creative prompts and challenges, Self-improvement articles, Interviews with successful creatives, Resources and tools, innovative ideas and discuss about the various thought process that will continuously improve our thought process day by day.

Let us see here few posts of https://brightideaspace.com/

The Psychology Of Facing New Challenges And How To Overcome Them

Green Building Materials: A Guide To Sustainable Construction

The Top 10 Sustainable Cities In The World And Their Clean Energy Innovations

The Role Of Tree Relocation In Sustainable Development

How Does Laser Cleaning Work? A Comprehensive Guide

Living With Purpose: Finding Your Passion And Living A Meaningful Life

The Importance Of Living Life To The Fullest: Why Giving Your 100% Matters

9 Easy Ways To Reduce Plastic Waste In Your Daily Life

Prioritizing What’s Important: Understanding What Truly Matters In Life And Focusing On Those Things

How To Implement Your Strategic Plan: A Step-By-Step Guide

From ‘Good’ To ‘Great’: How To Build On The Momentum Of A Good Day

The Power Of Positive Self-Talk: Why A Bad Day Doesn’t Mean You’re Failing

The Top 10 Must-Read Personal Development Books For Success

Kanban: A Japanese Method To Overcome Laziness And Organize Your Tasks Efficiently

The Importance Of A Growth Mindset In Decision-Making: How To Adopt A Positive And Open Attitude Towards Making Decisions

This comment has been removed by a blog administrator.

Popular Posts

Companies with better product qualities and services

- Bright Idea Space

Search The Topic Here

Drop mail id and join us.

Enter your email address:

Delivered by FeedBurner

Collaborations

IMAGES

COMMENTS

The frictional losses are referred to as . major losses (h. l) while losses through fittings, etc, are called . minor losses (h. lm). Together they make up the . total head losses (h. lT) for pipe flows. Hence: h. lT = h. l +h. lm (1) Head losses in pipe flows can be calculated by using a special form of the energy equation discussed in the ...

Experiment #4: Energy Loss in Pipes 1. Introduction. The total energy loss in a pipe system is the sum of the major and minor losses. Major losses are associated with frictional energy loss that is caused by the viscous effects of the fluid and roughness of the pipe wall.

2 2 Dg where , hf = loss of head due to friction L = length of pipe D = diameter of pipe V = mean velocity of flow in the pipe f = Darcy Weisbach friction factor. In addition to energy or head loss due to friction, there are always head losses in pipes due to an enlargement or contraction of the flow section, bends, junctions, valves etc ...

Major losses create a pressure drop along the pipe since the pressure must work to overcome the frictional resistance. The Darcy-Weisbach equation is the most widely accepted formula for determining the energy loss in pipe flow. In this equation, the friction factor (f), a dimensionless quantity, is used to describe the friction loss in a pipe.

In fluid flow, major head loss or friction loss is the loss of pressure or “head” in pipe flow due to the effect of the fluid’s viscosity near the surface of the pipe or duct. Major head losses are a function of: flow regime (i.e., Reynolds number), flow velocity, pipe diameter and its length, friction factor (flow regime (i.e., Reynolds ...

between the fluid and the pipe wall. We account for this friction using the loss or the head loss term in the MEE. In this experiment, w e will measure the head loss in a water as it goes through a straight section of circular polyvinylchrolide (PVC) pipe with constant cross-sectional area for a . gz w loss P V gz P V + + = + + 1 + in, net. − ...

2.3 Calculation of Head Loss 2.3.1 Major losses The major head loss in pipe ows is given by Eqn. 3. h l = f L D V2 2g (3) Here, L and D are the length and diameter of the pipe, respectively, V is the average uid velocity through the pipe and f is the friction factor for the section of the pipe. In general, the friction factor is

The objective of this experiment is to determine the loss coefficient (K) for a range of pipe fittings, including several bends, a contraction, and an enlargement. Introduction: Two types of energy loss predominate in fluid flow through a pipe network; major losses, and minor losses. Major losses are associated with frictional energy loss

Experiment #3: Energy Loss in Pipe Fittings 1. Introduction. Two types of energy loss predominate in fluid flow through a pipe network; major losses, and minor losses. Major losses are associated with frictional energy loss that is caused by the viscous effects of the medium and roughness of the pipe wall.

Head loss in pipe flow system due to viscous effect i.e. due to friction will be termed as major head loss and will be indicated by h L-Major. Head loss in pipe flow system due to various piping components such as valves, fittings, elbows, contractions, enlargement, tees, bends and exits will be termed as minor head loss and will be indicated ...